OEM chalcogenide glasses Factory – Silicon Lens(Si lens) for Infrared Applications – Wavelength

OEM chalcogenide glasses Factory – Silicon Lens(Si lens) for Infrared Applications – Wavelength

OEM chalcogenide glasses Factory – Silicon Lens(Si lens) for Infrared Applications – Wavelength Detail:

Product information:

Silicon lens is optical lens made of silicon. Silicon (Si) is a crystalline material that is commonly used in infrared optical systems operating in the 3 to 5µm spectral band. Its refractive index is near 3.4 throughout the range. It has comparatively low densities between common infrared materials, which is only half that of Ge, GaAs and ZnSe. Thus silicon material is ideal choice for system with weight concerns. Silicon is also harder and cheaper than most of the common infrared materials, reduce the material cost while increase the fabrication cost at the same time.

Silicon is well suited for MWIR application but due to the strong absorption above 6 micron, it is not suited for LWIR application. It could also be used as a mirror substrate for laser application due to its thermal conductivity, light weight, and hardness.

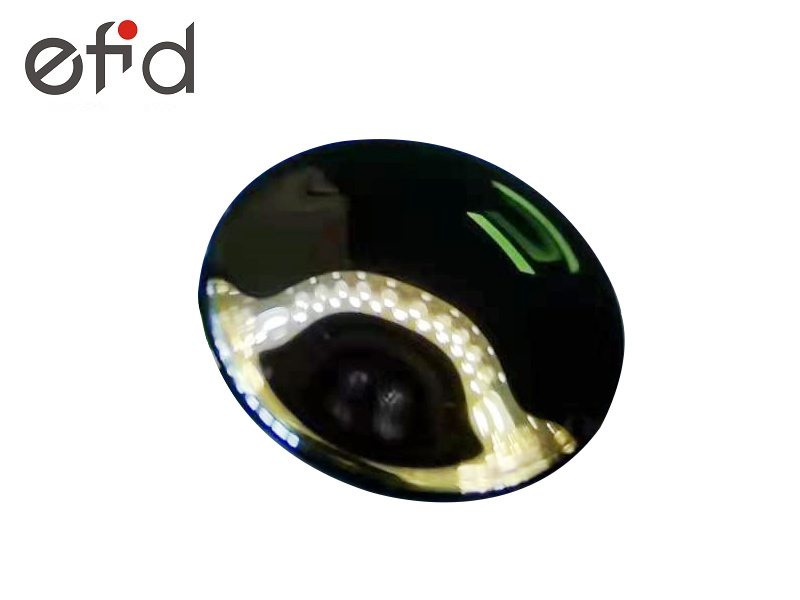

Wavelength Infrared can manufacture a variety shape of silicon lens with plane, concave, convex, aspheric and diffractive surfaces. Silicon is most popular for systems operating in the 3-5µm spectral region, with anti-reflective coatings (AR coating), the average transmission could be brought up to 98%. We can also apply diamond-like carbon coating (DLC coating) or high durable coating (HD coating) on lens surface to provide extra protection against scratch and impact.

Wavelength infrared manufactures quality custom spherical and aspheric silicon lens. They can either focus or diverge incoming light beam to meet specific requirement of the infrared system.

Specifications:

| Material | Silicon(Si) |

| Diameter | 10mm-300mm |

| Shape | Spherical or Aspheric |

| Focal length | +/-1% |

| Decentration | <1’ |

| Surface figure | <λ/4 @ 632.8nm (Spherical surface) |

| Surface irregularity | < 0.5 micron (Aspheric surface) |

| Clear Aperture | >90% |

| Coating | AR or DLC |

Remarks:

1.DLC/AR coating is available upon request.

2.Customization available for this product to suit your technical requirements. Let us know your required specifications.

Product detail pictures:

Related Product Guide:

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our administration ideal for OEM chalcogenide glasses Factory – Silicon Lens(Si lens) for Infrared Applications – Wavelength , The product will supply to all over the world, such as: British, Slovakia, Latvia, We have many years' experience in hair product production, and our strict QC Team and skilled workers will ensure that we give you top hair products with the best hair quality and workmanship. You will get successful business if you choose to cooperate with such a professional manufacturer. Welcome your order cooperation!

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.

PRODUCT CATEGORIES

Wavelength has been focused on providing high precision optical products for 20 years